Sum the total amount of gold in your leach tanks, absorption tanks, carbon out of circuit and gold on wool to provide a total gold in circuit. You may also want to work out your volume of your eluate and assay that too for accuracy but this provides very little gold to the inventory.

If there is gold on your wool, for each strip on the wool subtract your barren assay from your loaded assay and multiple by your column size. sum the total gold attributed to carbon out of circuit for each of the hoppers/columns.if you loaded carbon is 9 tonnes and your assay is 3500ppm then 9 X 3500 will give your gold in that hopper. work out the tonnes of carbon in your acid wash column, elution column regen hopper basically wherever you store carbon at that point in time. Work-out where the carbon is in your circuit.do the same for each tank and sum the total gold in every tank.

Sum with the gold in solution and in solids to get the total gold content for that tank.

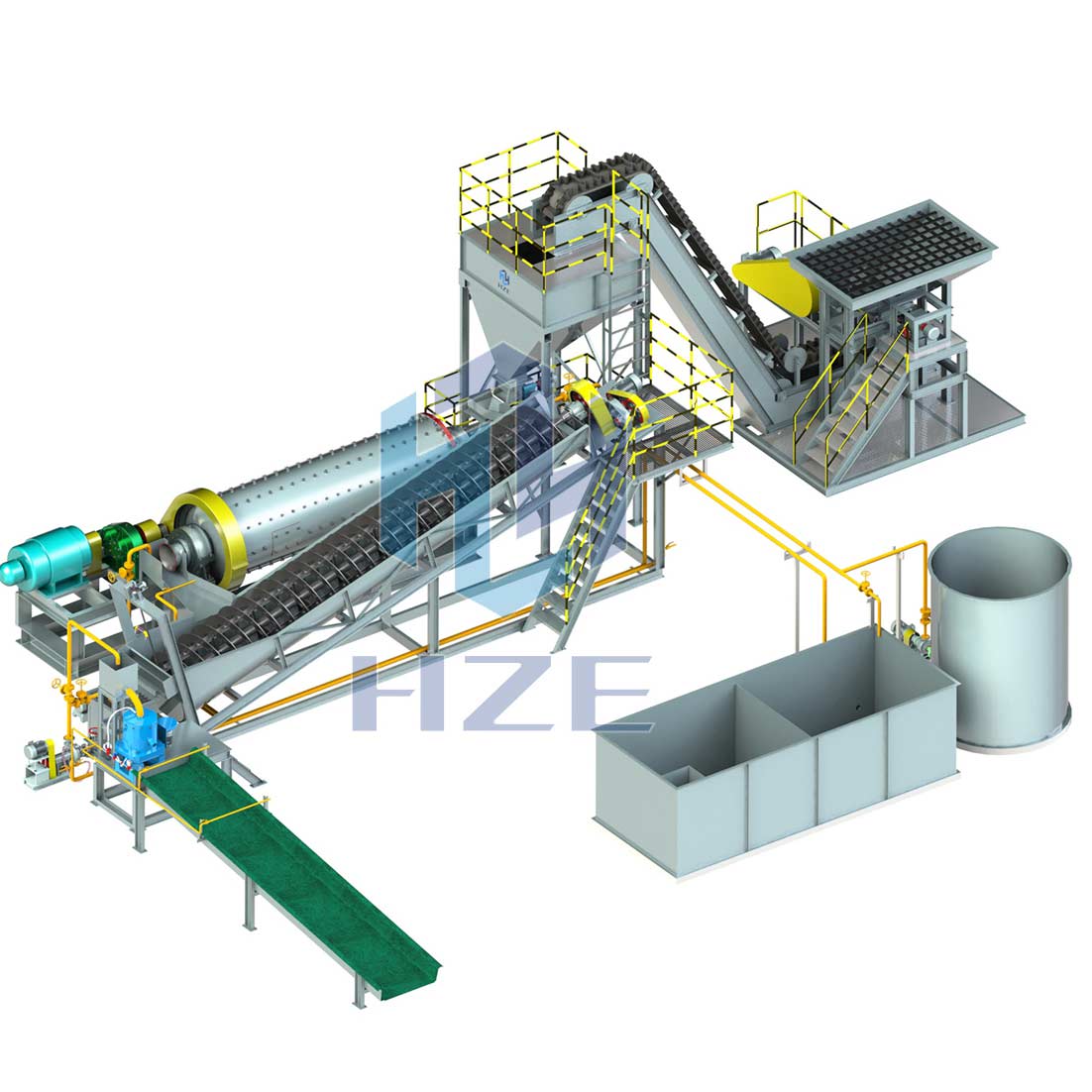

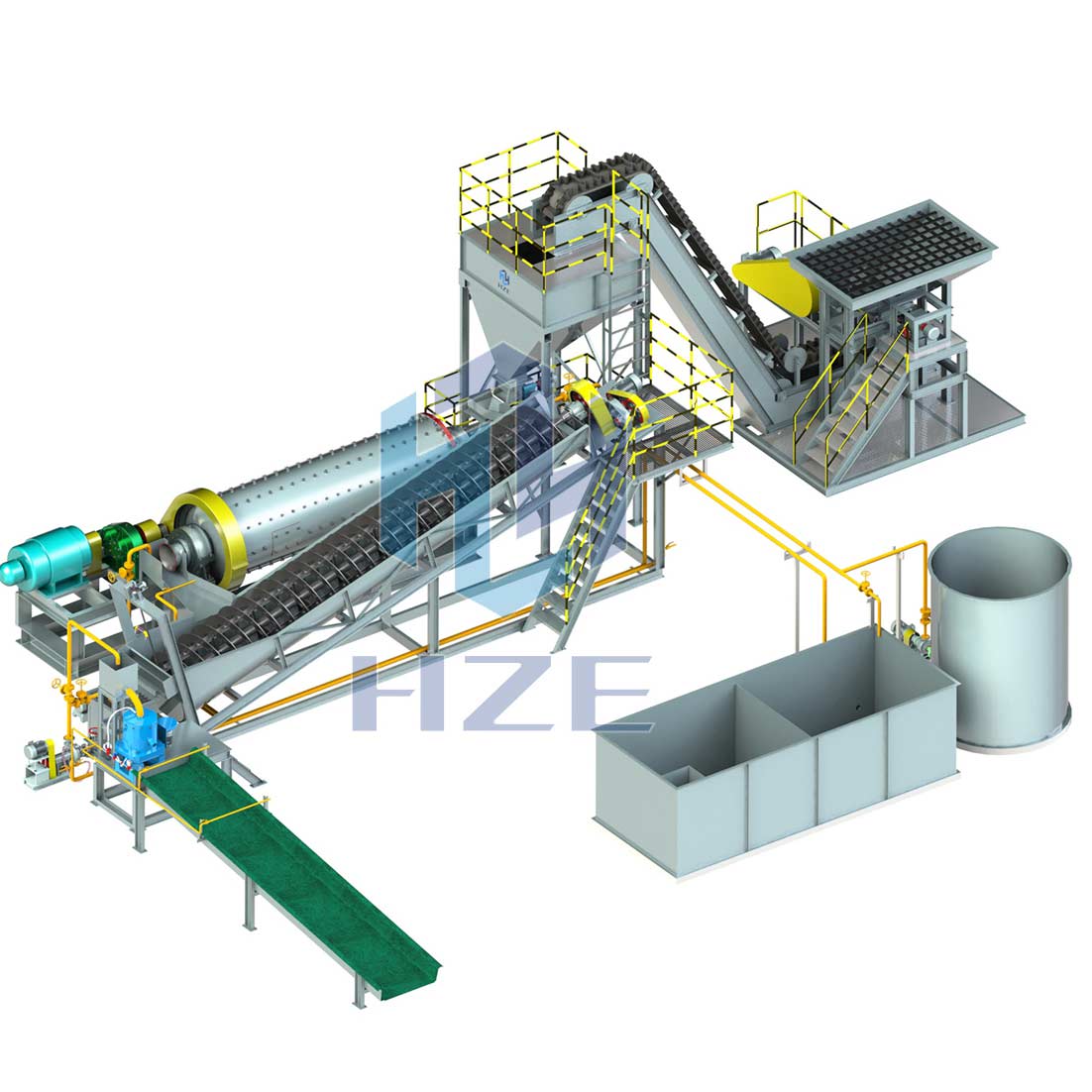

multiple out your assay value to your carbon tonnage to get the total gold in carbon. given the tank volume and the mass of carbon per 2l you can work out your total carbon tonnage in the tank.  collect a 2l slurry sample and pass through a 850um screen to collect the carbon. same as leach tanks but need to also account for gold on carbon. do this for each leach tank and sum the total gold in the leach circuit. calculate the gold attributes to the solids in the tank and the gold in the solution of the tank based on the density and tank volume. weight solids cake and calculate the % solids in the tank. Filter the entire sample collecting a solution sample and solid cake sample. Its principal operations are located in Siberia and the Russian Far East: Krasnoyarsk, Irkutsk and Magadan regions and the Republic of Sakha (Yakutia).Hydrometallurgy: Leaching in Heap, Vat, CIL, CIP, Merrill–Crowe, SX Solvent Extraction The company says it demonstrates the lowest production costs among major global gold producers. Polyus is the world’s fourth-largest gold mining company by production volumes and the largest gold miner in terms of attributable gold ore reserves. This resulted in the recovery rate at Verninskoye reaching around 90% in February 2021. And as part of the project, Polyus implemented a number of initiatives aimed at improving recoveries, including the installation of an additional reactivation kiln in the main building extension, as well as installation of an additional centrifugal concentrator in the main building. The gravity concentration circuit was equipped with additional centrifugal concentrators and a hydrocyclone unit which were also installed in the main building extension. An additional cone crusher and screens were installed to reduce recirculation and increase the throughput capacity of the existing SAG mill. This included the installation of an additional crushing circuit comprising of a ball mill and two vibrating screens in the extension of the main building.

collect a 2l slurry sample and pass through a 850um screen to collect the carbon. same as leach tanks but need to also account for gold on carbon. do this for each leach tank and sum the total gold in the leach circuit. calculate the gold attributes to the solids in the tank and the gold in the solution of the tank based on the density and tank volume. weight solids cake and calculate the % solids in the tank. Filter the entire sample collecting a solution sample and solid cake sample. Its principal operations are located in Siberia and the Russian Far East: Krasnoyarsk, Irkutsk and Magadan regions and the Republic of Sakha (Yakutia).Hydrometallurgy: Leaching in Heap, Vat, CIL, CIP, Merrill–Crowe, SX Solvent Extraction The company says it demonstrates the lowest production costs among major global gold producers. Polyus is the world’s fourth-largest gold mining company by production volumes and the largest gold miner in terms of attributable gold ore reserves. This resulted in the recovery rate at Verninskoye reaching around 90% in February 2021. And as part of the project, Polyus implemented a number of initiatives aimed at improving recoveries, including the installation of an additional reactivation kiln in the main building extension, as well as installation of an additional centrifugal concentrator in the main building. The gravity concentration circuit was equipped with additional centrifugal concentrators and a hydrocyclone unit which were also installed in the main building extension. An additional cone crusher and screens were installed to reduce recirculation and increase the throughput capacity of the existing SAG mill. This included the installation of an additional crushing circuit comprising of a ball mill and two vibrating screens in the extension of the main building.

Gravity circuit gold mining upgrade#

Polyus has completed a number of initiatives to upgrade the crushing and grinding circuit at Verninskoye. Capital expenditures for the project amounted to some $60 million, in line with the initial budget. This upgrade is expected to provide an additional 40,000 oz of incremental gold volumes at Verninskoye. The mill has now achieved its target hourly throughput rate of 450 t/h and is currently running at an annualised capacity of 3.5 Mt. The project,which was launched in the fourth quarter of 2019, has been completed ahead of its initial schedule (the second half of 2021). PJSC Polyus announces that it has successfully completed the expansion of the Verninskoye mill’s throughput capacity.

0 kommentar(er)

0 kommentar(er)